Food Safe Lubricators

Digilube Systems specializes in poultry processing lubricators built for high-speed, food-safe production environments. We design our lubricators and H1 lubricants to extend chain life while reducing overall operating costs. Digilube’s all electric high speed lubricators deliver a precise, controlled application of lubricant to critical chain wear points reducing waste, and preventing contamination, while significantly extending chain life.

We engineer our Bolted Chain Lubricators and Logging Chain Lubricators specifically to perform in the harsh, washdown-intensive environments of poultry and food processing facilities. These systems enhance equipment reliability while supporting strict food safety standards.

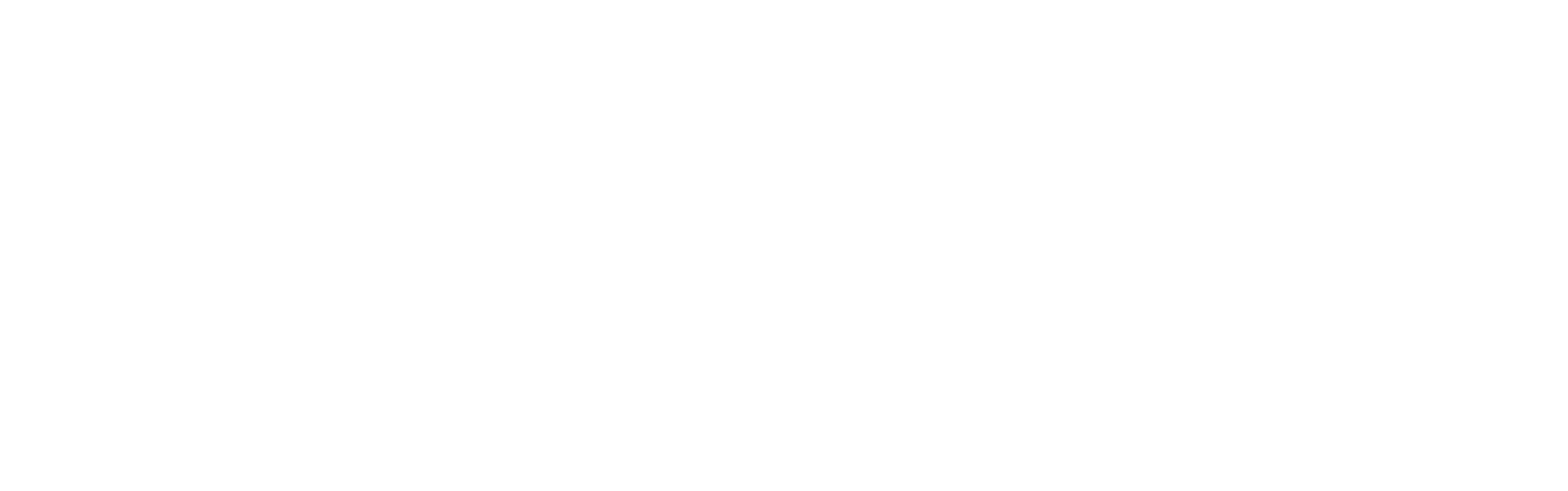

Bolted Chain Lubricator

Poultry processors frequently use bolted chain systems in evisceration, chilling, cutting, and packaging areas. Digilube’s Bolted Chain Lubricators ensure:

- Controlled application to lubricate the chain wear points & trolleys

- Reliable lubrication during long production cycles

- Reduces friction and extends chain life

- Reduced maintenance labor and safety risks

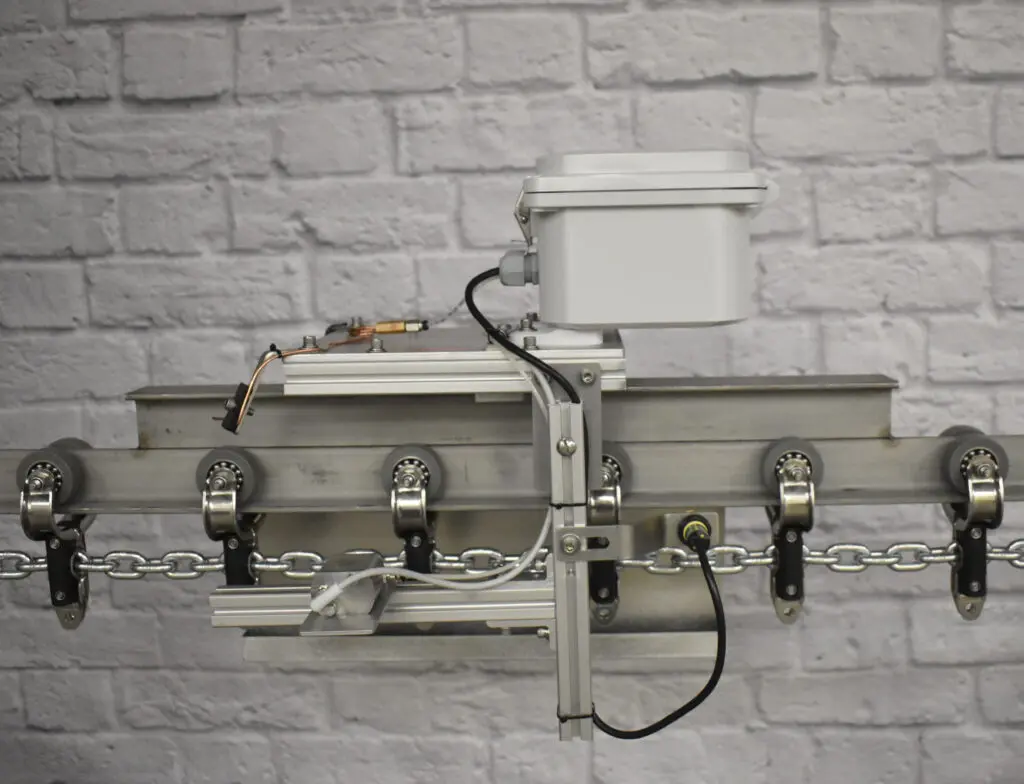

Logging Chain Lubricator

Digilube engineers its Logging Chain Lubricators to deliver lubricant precisely to high-wear areas such as chain pins and bushings. Perfect for cold, wet, and high-speed poultry applications, these lubricators:

- Apply lubricant accurately with minimal overspray

- Offers complete chain lubrication preventing scale & rust

- Minimize equipment downtime and manual lubrication

- Prevent excess oil that could impact sanitation or product zones

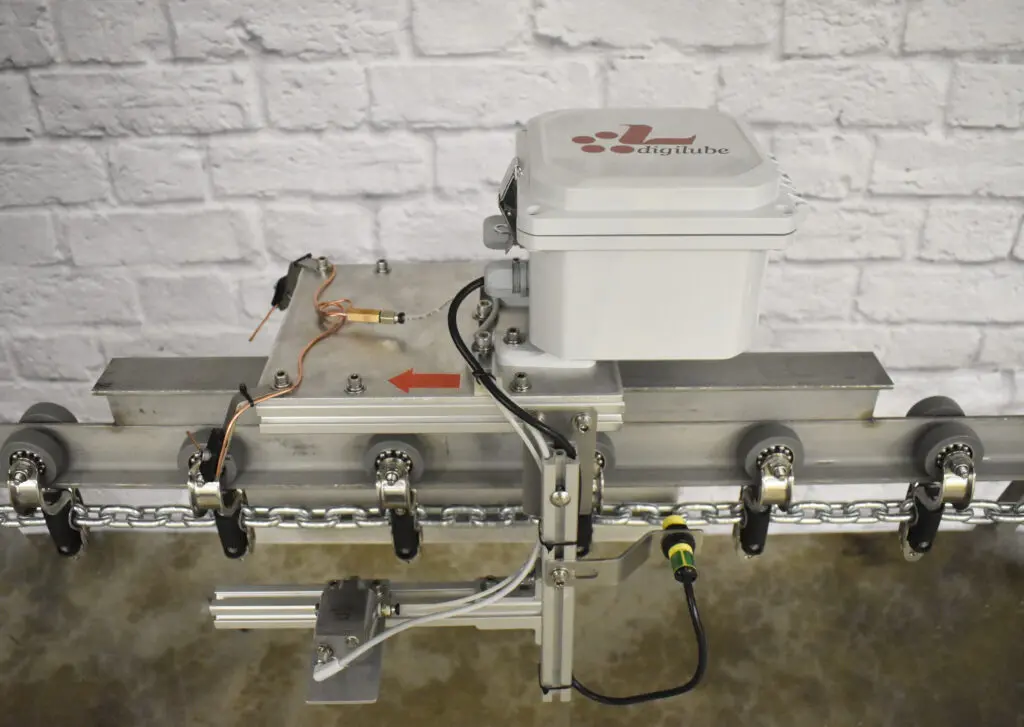

New! Precision Spray Nozzle for Logging Chains

Digilube developed its new Spray Nozzle as an optional add-on specifically for logging chain lubricators in poultry plants. This enhancement ensures high-precision lubricant delivery, improving penetration into chain links and optimizing performance.

- Accurate spray patterns

- Reduce rust & scale

- Consistent coverage on fast-moving chains

- Reduce lubricant consumption

- Designed for harsh processing environments

Food-Grade Lubricant:

Ultra-Film FG

Digilube recommends Ultra-Film FG, our premium NSF H1-certified food-grade lubricant, ideal for use where incidental food contact is possible.

We produce Ultra-Film FG using high-pressure hydrotreatment to ensure exceptional purity and stability. This proprietary formula includes a synthetic non-petroleum EP component and a thin-film lubricant specifically designed for food processing equipment.

Features & Benefits

- Excellent extreme-pressure performance

- Maximum wear protection in high-load or shock-load environments

- Eliminates rail dust for a cleaner operating area

- Superior rust and acid resistance

- Exceptional oxidation stability for extended service life

- Reconditions metal surfaces to reduce friction

- Complies with NSF International H1 food-safety standards

- Safe for sanitation cycles and will not leave residue on chains

Applications

- Machinery that processes, transports, or packages food

- Overhead and in-floor conveyors

- High-load industrial applications requiring food-grade lubrication