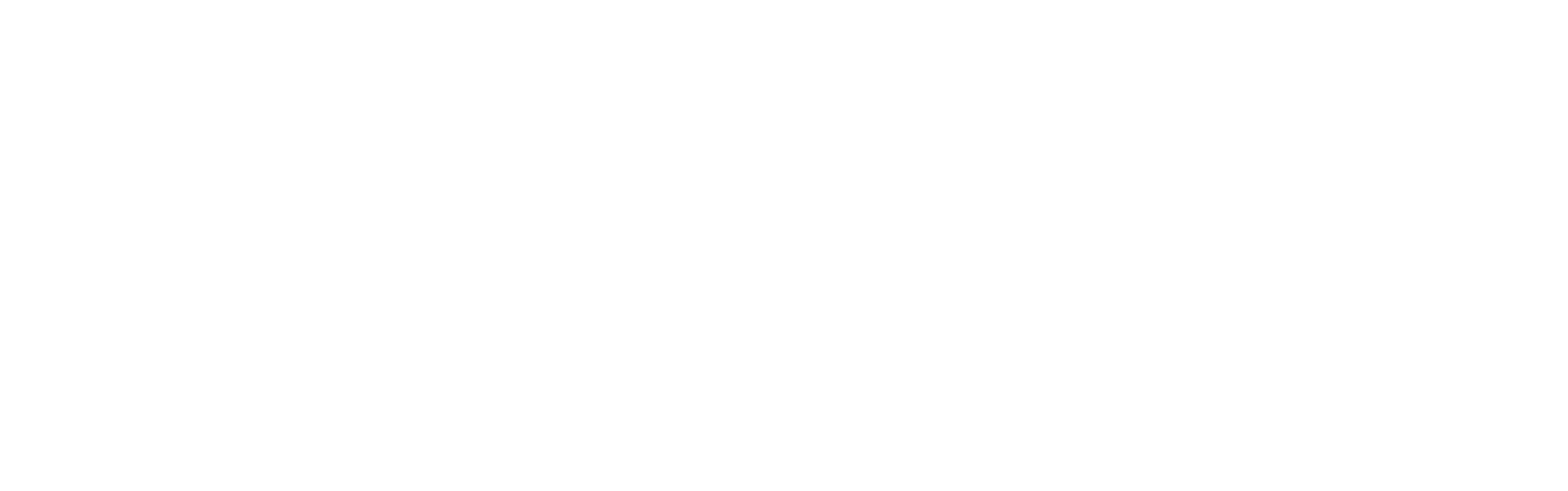

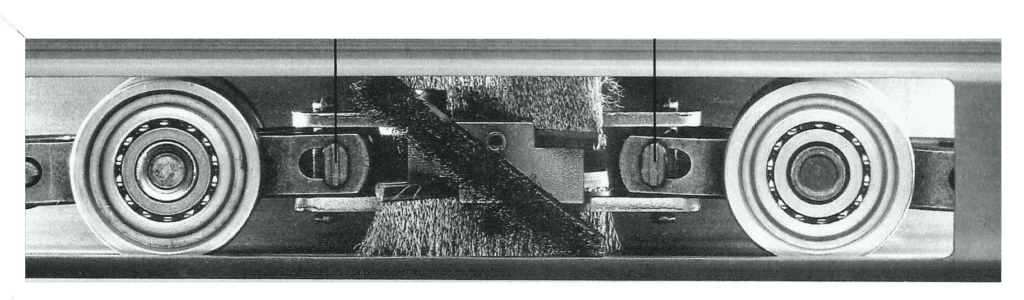

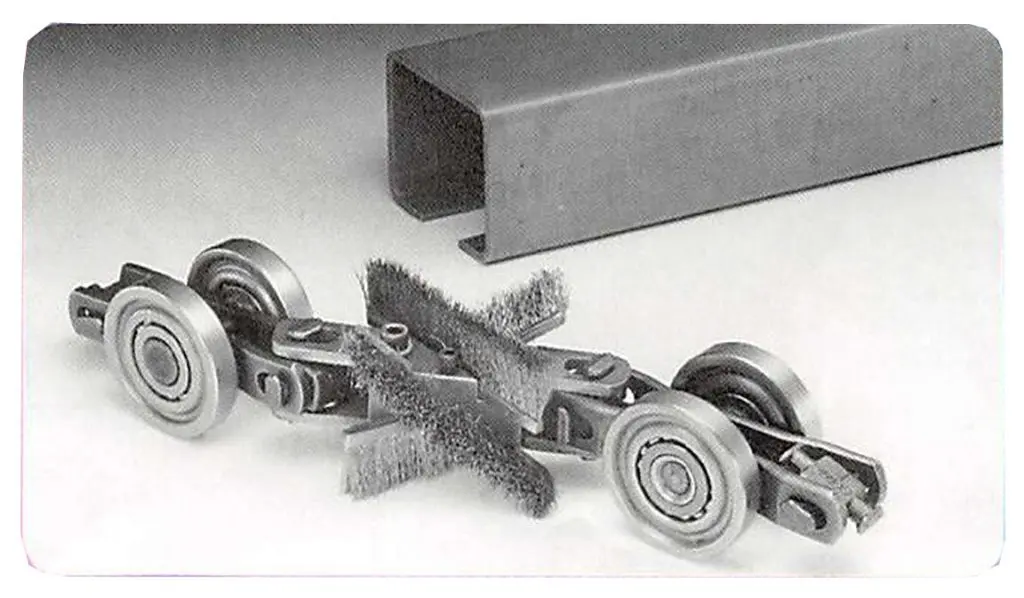

Enclosed Track Conveyor Brush Cleaners

CONTINUOUS CLEANING

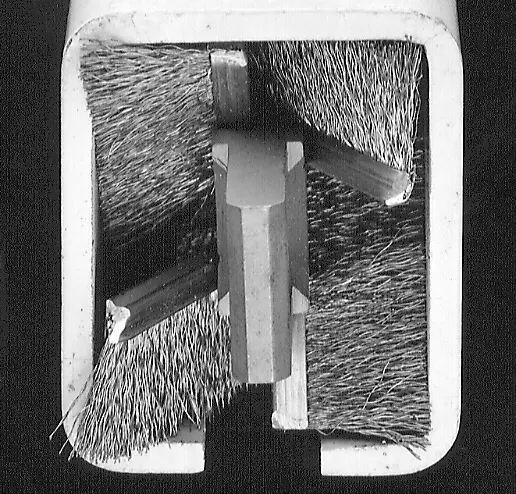

Non-Powered, conveyor brush cleaners for chains and rails are your best choice for continuous cleaning. The enclosed track brush cleaner is not only an easy way to make sure your enclosed track does not have excessive build-up but also reduces possible contamination on the product. There are two types of brushes that are available, stainless steel and bronze.

For enclosed tracks with a significant amount of build-up, we recommend you start with the stainless steel brush. After the track is cleaned a few times, a bronze brush which tends to be softer, would be used for maintenance on the track.

REPLACEMENT BRUSHES

Eventually over time, the brushes on the item will wear down and will need to be replaced. It is recommended to buy an extra set of brushes with the initial assembly thus avoiding costly downtime. After installing your brushes, make note of how long your brushes last before they need to be replaced. This will help you effectively prepare for your next set of replacement brushes. Below you can find brushes that fit Enclosed Track type rails, as well as how many replacement brushes are needed for one assembly.

FITS WEBB UNIBILT CONVEYOR 20200

For best results, install the bronze (S91300) or stainless steel (S91300-S) Channel Sweep every 75-100 feet of chain. Replacement brushes will need to be purchased in sets of four and come in bronze (S93102) and stainless steel (S93106).

FITS RICHARDS-WILCOX MODEL 2035

For best results, install the bronze (S91310) or stainless steel (S91310-S) Channel Sweep every 75-100 feet of chain. Replacement brushes will need to be purchased in sets of four and come in bronze (S91312) and stainless steel (S91316).

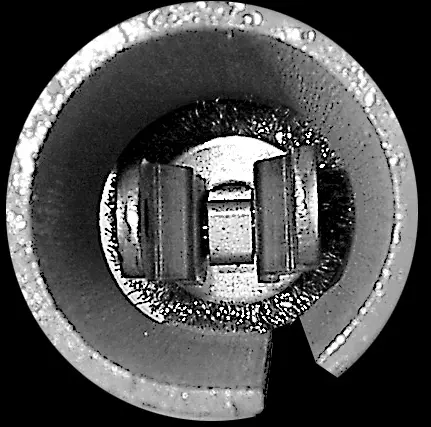

FITS ADAMS ROUND CHAINVEYOR 200 SERIES

For best results, install (91330) Channel Sweep every 75-100 feed of chain.

This assembly only needs one replacement brush, and is available in stainless steel (S91332) only

Benefits of Enclosed Channel Brush Cleaners

| PROVIDES: | Continuous Cleaning of all Internal Surfaces Ease of Installation Non-Sparking Brushes Two types of brushes to fit your cleaning needs |

| ELIMINATES: | Particulate Build-Up & Fall Out Rework of Finished Parts Wheel & Chain Wear Costly Down Time |

Looking to clean I-Beam type Conveyors? Click here