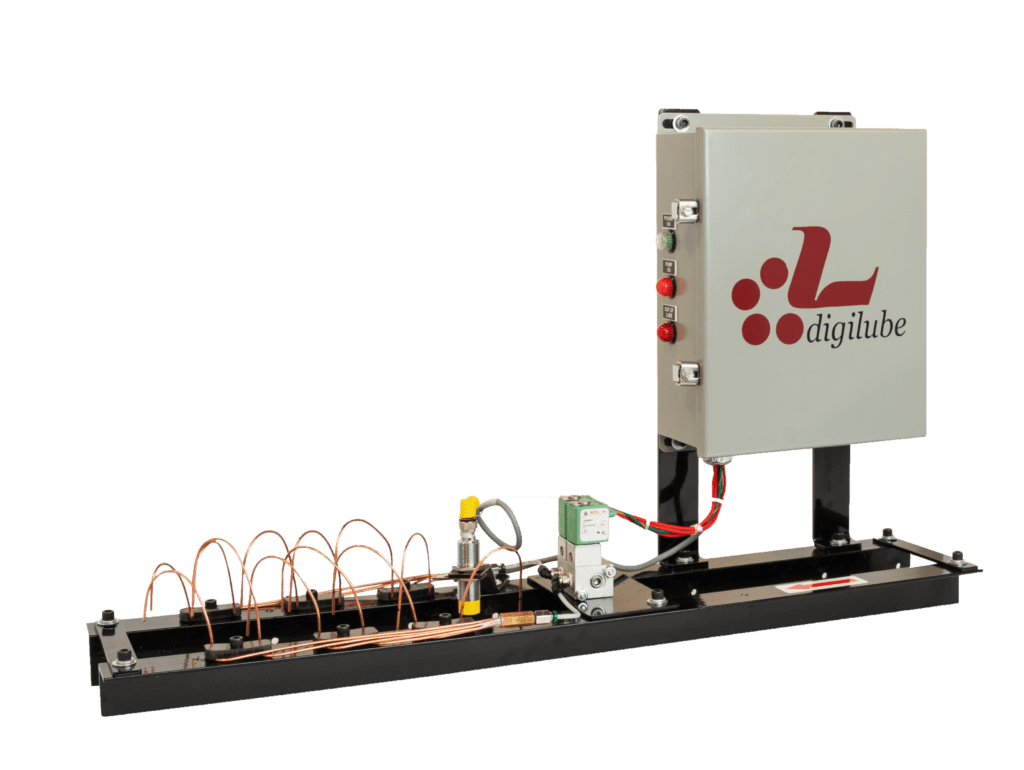

Enclosed Track Lubricators

Smaller (shorter) systems that require minimal lubrication are what our Enclosed Track systems are best used for. We typically mate a 12 gallon tank with our Enclosed Track Lubricators and some I-Beam Conveyors.

This microprocessor-based conveyor equipment is capable of dispensing high temperature conveyor lubricant onto:

- Daifuku Webb Unibilt enclosed track conveyors

- Rapid Industries Rapidflex conveyor

- Richard Wilcox’s Zigzag

- Twin-Trak conveyors

- Allied Enclosed Track Overhead Conveyors

- Gregory Adam’s Overhead Series 200 and 300 conveyors.

Each piece of conveyor lubrication equipment mounts at the point of application. A 15” long slot is cut out on top of the rail and the lubricators fit over the opening. They lubricate the vertical load wheels, horizontal guide rollers and pivot points and optional swivels.

The Enclosed Track Lubricators connect to a nylon lubricant supply tubing, that connects to either a 12 gallon Self Contained Lubrication System or a centralized 65 gallon tank.

Digilube’s Self Contained Lubrication System with a 12 gallon tank is installed near a column or close to the lubricator for ease of filling. We recommend a 65 gallon lubricant tank when a larger amount of lubricant is used and when you have longer chain links or when chains are subject to high temperature ovens for powder coatings; including organic and inorganic coatings. Many times conveyors go through washers, ovens, and paint booths which increase lubricant consumption, which is why in this case, a 65 gallon tank is recommend.

Features

- Microprocessor controlled

- Millisecond dispensing accuracy

- Field programmable security code

- Large 2-line LCD screen

- 16 button programmable key pad

- 4 independent channels

- Sturdy dispensing tubes resist vibration

- PC interface contacts (optional PLC contacts)

- Automatic fault shut-down

- All electronic

- 1 year warranty

- 3 year microprocessor warranty

Types of Enclosed Track Lubricators

| DL-121 | Enclosed Power Chain Lubricator |

| DL-121i | Inverted Enclosed Track Lubricator |

| DL-121FC | Enclosed Track Free Carrier Lubricator |

| DL-143PF | Enclosed Power Chain & Free Carrier Lubricator |

Specifications

| POWER SOURCE | 120VAC or 24VDC |

| DIMENSIONS | 28″L x 17″H x 6″W |

| LUBRICANT POINTS | Vary depending on Lubricator |